I decided to begin with a small, simple job first and work my way up.

|

|

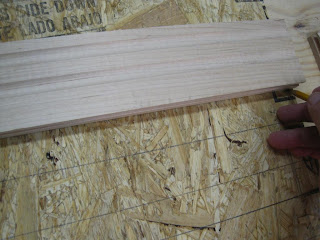

I cut the AdvantTech base to exact size on the table saw and

then used the table saw to trim the tongue off the first edge and the groove

off the last.

|

|

|

I

followed that up with a pass across the jointer to produce a flat, smooth

surface.

|

|

|

Then to

the sliding miter saw for careful trim of left edge.

|

|

|

A quick

check of first two showed that the saw was cutting neither square or even

straight edges!

|

|

|

So the

old Ryobi power miter box (bought when we applied trim in house 25 years ago!)

came out and produced perfect edges.

|

|

|

A little

playing with available pieces yielded an acceptable layout.

|

|

|

By

carefully looking at all available pieces, I was able to keep the scrap to an

incredibly small amount!

|

|

|

I decided

to glue each course with Titebond III, a glue rated for outdoor use but to use

screws to produce the required clamping pressure while the glue set.

|

| ||||

| I drilled a grid using my little B&D Lithium Ion pocket drill. |

|

|

The

Titebond III instructions call for a generous application!

“The

bigger the blob, the better the job!”

|

|

|

Wipe away excess glue with a damp cloth

|

|

|

C-clamps

hold the piece in place while I . . . .

|

|

|

Use my

3/8 Milwaukee

variable speed drill to seat the 1.25” fine thread drywall screws.

|

|

|

These

brushes worked very well indeed and the Titebond III was easy to apply.

|

|

|

Edge and

end clamps hold the second course while I carefully invert the piece to apply

the screws in the back.

|

Worked

like a charm! But left me with a piece that had to stay in the clamp overnight.

Tomorrow,

drill second course of holes vertically and add final three courses of

flooring.

I am so

glad I decided to do this little roll-around cart top first since it allows me

to learn on a non-critical piece.

No comments:

Post a Comment